In 2014, steady growth drove us to relocate into a new 42,500-square-foot facility designed to maximize quality, efficiency, and safety. We expanded even further in 2020 with a second 40,000-square-foot facility.

However, it’s not the location or the technology that makes the difference — it’s our people. In each of our departments, you will find skilled employees dedicated to driving quality into every part that we deliver.

Our engineering, R&D, and production teams provide solutions to the most critical applications in the world. So send us a drawing, a model, a sample, or share an idea. Because when results count, you can count on Polycraft.

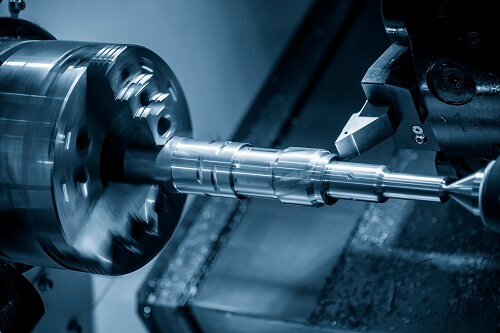

Polycraft’s machine shop supports our customers as well as internal tooling and fixturing needs using multiple CNC mills, lathes, Machining centers, and a Mazak Integrex. We can turn stock up to 24 inches in diameter. We are set up for tolerances greater than +/- .001 inches in-house and have machining partners to help us with tighter tolerances when an assembly requires it.

With a customized mold, we can create a plastic product according to your unique requirements. Molten plastic can be formed into virtually any shape, making the injection molding process valuable to a wide range of projects.

The key to the custom injection molding process is creating a mold that meets all project specifications to a close degree. Our engineering team develops injection molds with a high level of precision for plastic products that meet project demands.

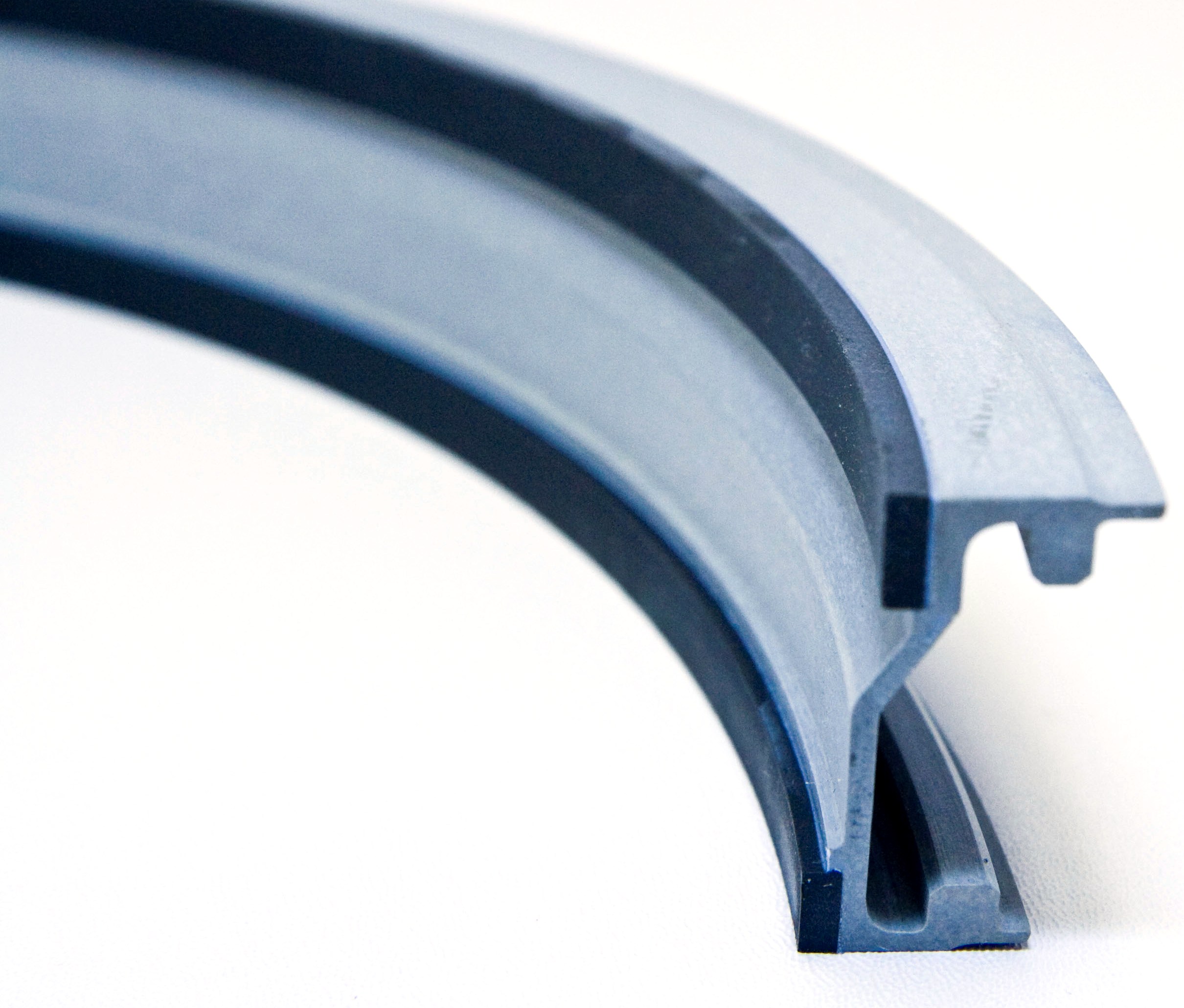

We work with silicone, fluorosilicone, FKMs such as Viton™, EPDMs, Natural Rubber, SBR, and others. We mold bellows, clamps, seals, vibration dampers, and covers. These can be reinforced with polyester, fiberglass, kevlar, and more. Depending on the application’s requirements, they can be bonded to metals or plastics.

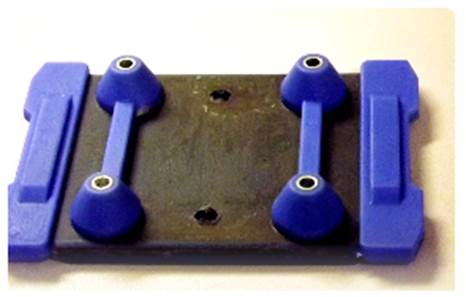

Our room-temperature vulcanizing (RTV) bonding department bonds metal, plastic, and elastomeric components in an environmentally monitored area. Our fixturing helps maximize repeatability and ensures that tight tolerances are held.

Our composite bonding department uses film adhesives to bond honeycomb, metal, seals, wear pads, and PTFE, commonly referred to as Teflon™. This special process ensures the optimal integrity of composite components for the aerospace sector and other industries. We have GT193 certification through GE Aerospace, certifying us to comprehensively analyze various materials and produce parts according to the certification’s standards.

We have a CCA (Controlled Contaminant Area) that meets the particulate count for an ISO 14644 class 8 clean room and use PLC’s to ensure tight ramp rates and repeatable cure profiles. These controlled environments use process control parameters that provide a continuously filtered air supply with the correct temperature and humidity to ensure optimal conditions for surface bond integrity and composite layup.

Our machine shop supports secondary operations like grinding and surface finishing to achieve final dimensions.

Our urethane molding department uses many different raw material vendors to provide a wide variety of part characteristics, including durometers ranging from Shore 10A to 80D with custom colors. We can bond onto metals or urethane parts to achieve significantly larger final dimensions. This process is ideal for advanced prototyping, product testing, and order qualities too small for high-speed injection molding.

In our vacuum forming department, we stock various grades and sizes of ABS and other thermoplastics for our Bel-O-Vac BV E Class 54-inch x 103-inch vacuum former. Vacuum forming works well for projects of nearly any size, offering enhanced efficiency and excellent repeatability over conventional production processes. A universal robot’s robotic arm can be programmed to trim parts, saving time and costs for our customers.

Parts are inspected by our quality control lab technicians, who utilize both touch and visual CMMs, laser scanners, and calibrated hand-held instrumentation to guarantee every component meets all quality requirements. We can engineer and build test fixtures when more in-depth part testing is required. This testing could include compression, expansion, cycle, high or low temperature, leakage, or burst testing.

Reach out to our team to discuss your latest project. Because when results count…count on Polycraft!